Unlocking the Secrets of SPBRC410: Why You Can’t Afford to Ignore It!

The world of technology and engineering is filled with innovations that continuously reshape our industries and everyday lives. One such innovation is SPBRC410, a term that may not be familiar to many but holds significant importance across various fields. This article aims to demystify SPBRC410 by exploring its specifications, applications, and why it is essential for professionals and enthusiasts alike to grasp its potential. By understanding what SPBRC410 is, how it works, and where it can be applied, readers can better appreciate its impact and relevance in today's fast-evolving landscape.

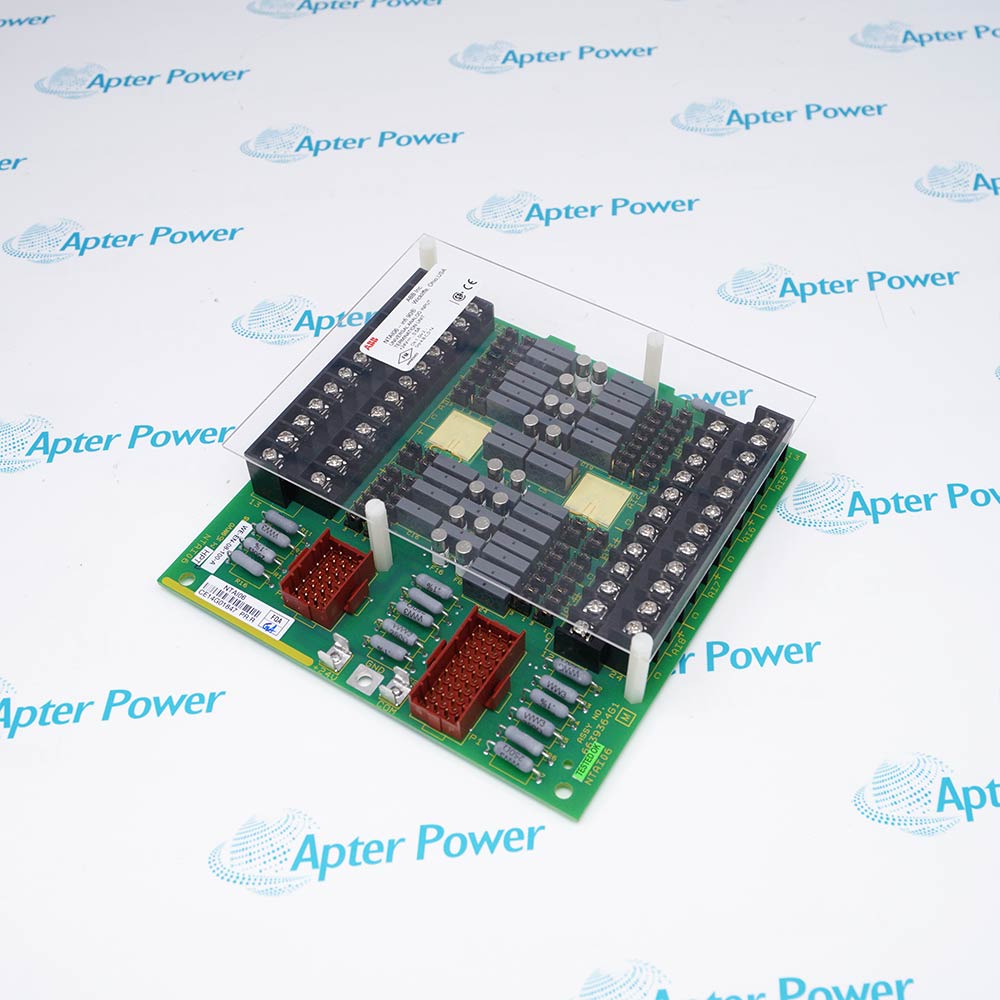

What is SPBRC410?

SPBRC410 is a cutting-edge material that has emerged as a game-changer in several industrial applications. Originating from extensive research and development, SPBRC410 was created to meet the growing demands for efficiency and performance in various sectors, including construction, manufacturing, and technology. What sets SPBRC410 apart is its unique composition and properties that enhance durability and functionality. For instance, a friend of mine, who works in a manufacturing plant, shared how switching to SPBRC410 for their machinery components drastically reduced downtime and maintenance costs. This tangible benefit showcases the material's relevance in practical settings, making it a noteworthy consideration for industry stakeholders.

Specifications of SPBRC410

The specifications of SPBRC410 are what truly define its effectiveness and applicability in various environments. This material exhibits remarkable tensile strength, making it resistant to wear and tear, which is crucial for components subjected to high stress. It adheres to stringent industry standards, ensuring that it can withstand extreme conditions without compromising performance. Notably, SPBRC410 has a defined thermal stability range, which allows it to perform optimally under temperature fluctuations. This feature was highlighted during a project my friend managed, where the material's thermal properties enabled it to maintain structural integrity in a high-heat environment. Additionally, its lightweight nature contributes to overall efficiency, making it desirable for applications where weight is a critical factor, such as in aerospace and automotive industries.

Applications of SPBRC410

SPBRC410's versatility allows it to be employed across a multitude of industries. In the construction sector, it is often used for reinforcing structures due to its superior strength and resilience. This has proven to be beneficial in earthquake-prone areas where building integrity is paramount. Furthermore, in manufacturing, SPBRC410 is utilized to create components that require durability and precision, such as gears and bearings. A fascinating application of SPBRC410 is in the technology field, specifically in the development of lightweight yet robust devices. My acquaintance, who is an engineer in the tech industry, recently remarked on how SPBRC410 enabled their team to innovate a new line of products that are not only lighter but also more efficient. The material's adaptability allows it to fit seamlessly into various production processes, leading to enhanced productivity and reduced costs.

Why Ignoring SPBRC410 is Not an Option

Neglecting to consider SPBRC410 could have serious implications for businesses and professionals in relevant fields. The risks associated with overlooking this innovative material include potential inefficiencies, higher operational costs, and missed opportunities for advancement. In competitive markets, staying ahead means leveraging the best materials available, and SPBRC410 offers significant advantages that can enhance product offerings and operational reliability. Moreover, as industries increasingly prioritize sustainability and performance, SPBRC410 stands out as a material that aligns with these goals, making it essential for forward-thinking companies to integrate it into their strategies.

Harnessing the Potential of SPBRC410

In summary, SPBRC410 is more than just a material; it is a pivotal element that can drive innovation and efficiency across various industries. By understanding its specifications and wide-ranging applications, professionals can harness its potential to enhance their operations and achieve greater success. Ignoring SPBRC410 is not just an oversight; it is a missed opportunity to leverage a transformative tool in today's fast-paced environment. I encourage readers to delve deeper into the possibilities that SPBRC410 offers and consider how it can be integrated into their respective fields for improved performance and productivity.